Pharmaceutical

The main goal of the pharmaceutical industry is to provide consumers with ethical drugs that prevent infections, maintain health, and cure diseases. This industry directly affects the global population, so a number of international regulatory bodies monitor things like drug safety, patents, quality, and pricing. Regulatory bodies include:

- US Food and Drug Administration (or FDA)

- World Health Organization (or WHO)

- Medicines and Healthcare Products Regulatory Agency (or MHRA)

The pharmaceutical industry is evolving and has made a great deal of progress over the last decade due to a research-oriented approach that has improved technologies, developed infrastructures, and increased research in the field of bioscience.

During the synthesis of some pharmaceuticals it is sometimes necessary to use solvents in order to increase the yield or purity of the product. After the pharmaceutical is produced, the solvent(s) are removed to the greatest extent possible. The products are then tested for any residual solvents in order to limit patient exposure. Residual solvents are separated into classes according to the risk to patient health.

Class 1 solvents are to be avoided at all costs as they are known to be human carcinogens or have adverse effects on the environment.

Class 2 solvents have less severe toxicities but should be avoided because of the potential of adverse effects.

Class 3 solvents have low toxicity and can be used when needed as long as they are below established limits.

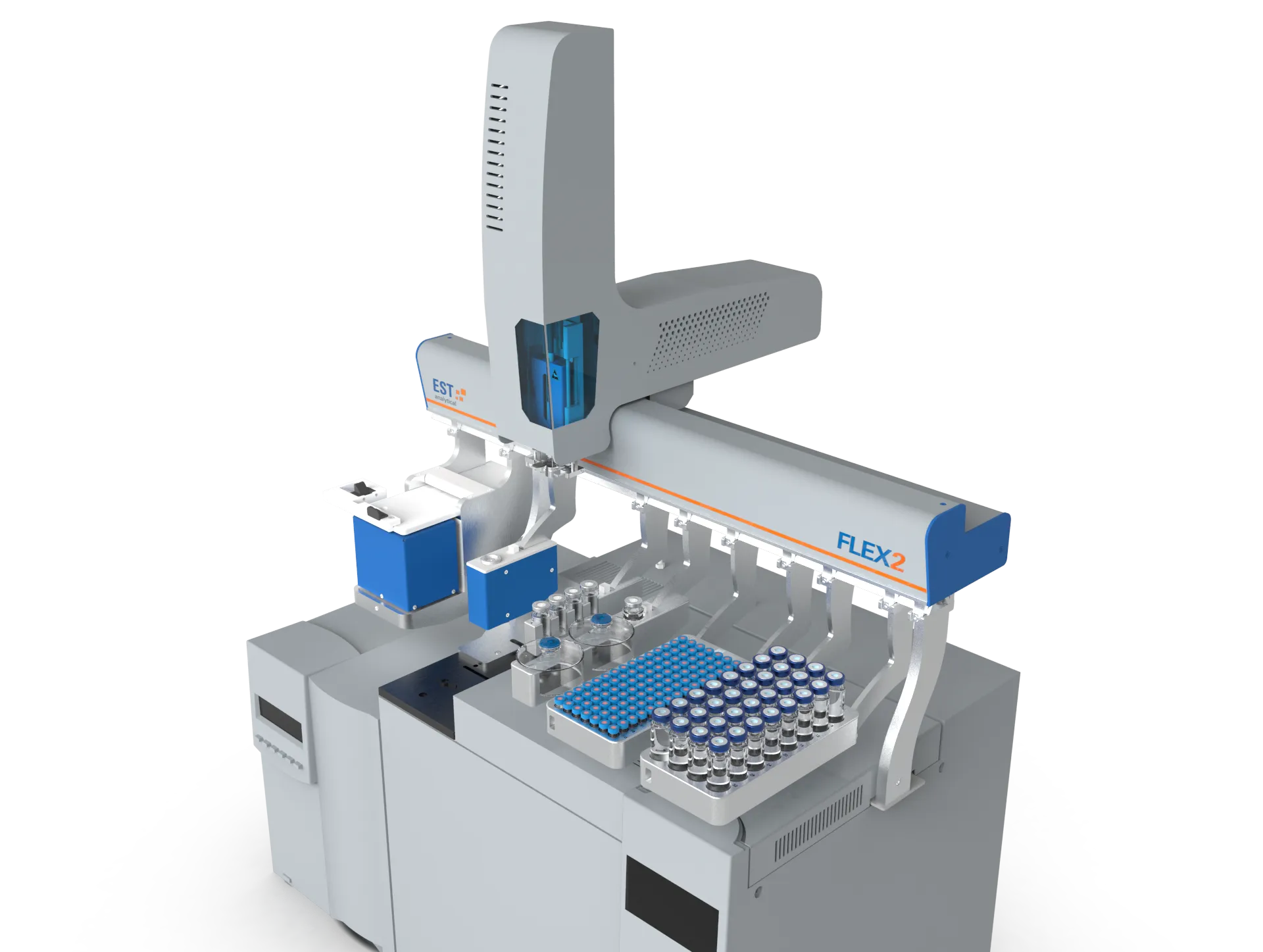

Pharmaceutical manufacturers are required to test for residual solvents in order to ensure that any residual solvents in the product are below established exposure limits. United States Pharmacopeia (USP) general chapter 467 describes a static headspace gas chromatography procedure for the determination of residual solvents.

Application Notes

During the synthesis of some pharmaceuticals it is sometimes necessary to use solvents in order to increase the yield or purity of the product. After the pharmaceutical is produced, the solvent(s) are removed to the greatest extent possible. The products are then tested for any residual solvents in order to limit patient exposure. Residual solvents are separated into classes according to the risk to patient health. Class 1 solvents are to be avoided at all costs as they are known to be human carcinogens or have adverse effects on the environment. Class 2 solvents have less severe toxicities but should be avoided because of the potential of adverse effects. Finally, Class 3 solvents have low toxicity and can be used when needed as long as they are below established limits. Pharmaceutical manufacturers are required to test for residual solvents in order to ensure that any residual solvents in the product are below established exposure limits. United States Pharmacopeia (USP) general chapter <467> describes a static headspace gas chromatography procedure for the determination of residual solvents. This application will demonstrate the USP <467> procedure using an autosampler configured with a gas tight syringe for static headspace sampling.

In 2018 and 2019, several blood pressure and heartburn medications were recalled due to cancer causing contaminants. Two of the problematic compounds were N-Nitrosodimethyl Amine (NDMA) and N-Nitrosodiethyl Amine (NDEA). Because these compounds have been found in several drugs, the drugs are considered unsafe. This application will follow the U. S. Food and Drug Administration method for the determination of NDMA and NDEA in drug products.