Environmental Industry and Regulated Testing

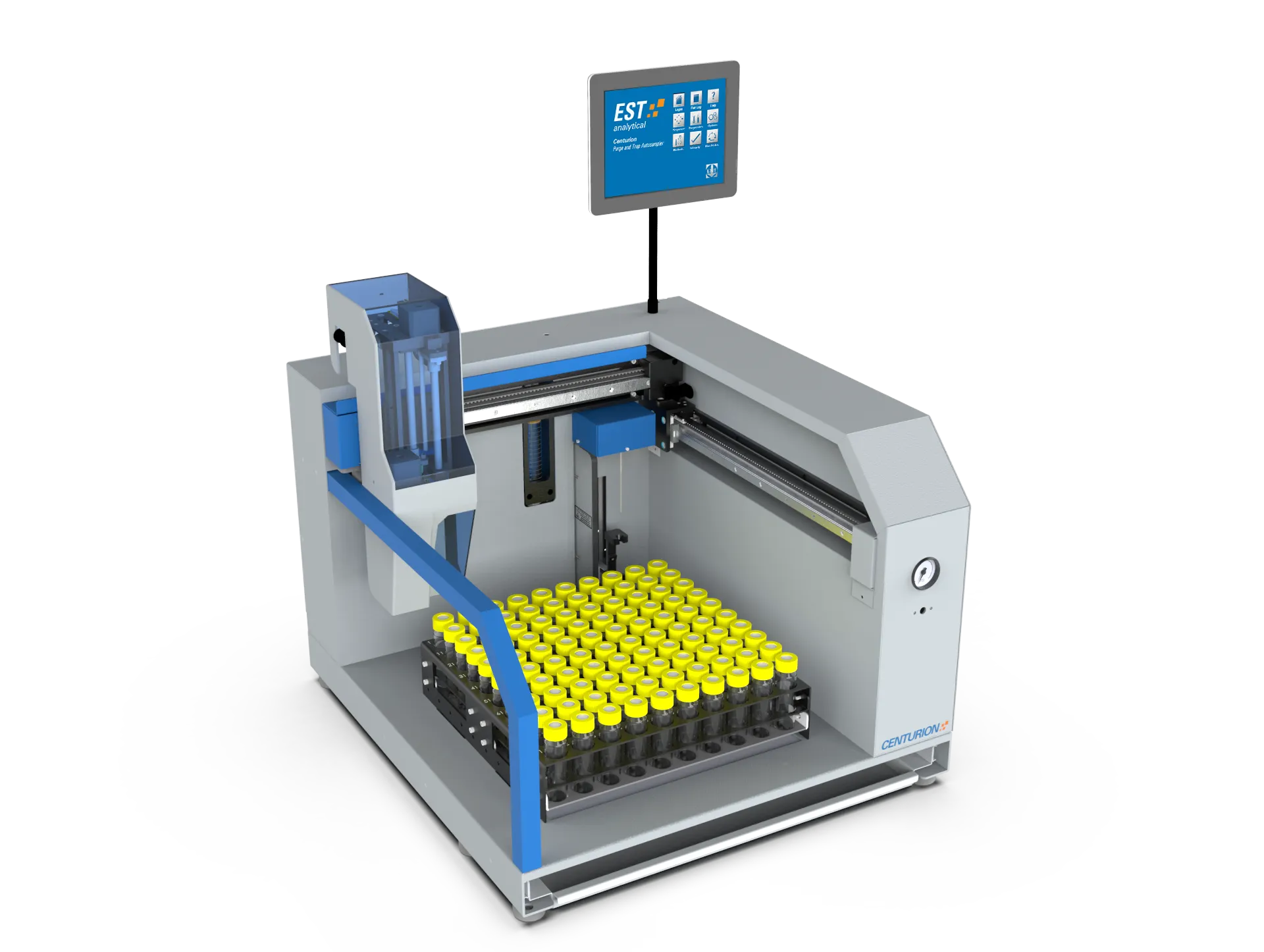

A common technique for the sampling of Volatile Organic Compounds (VOCs) is purge and trap concentration. During purge and trap concentration, the sample to be extracted is either placed in an airtight vial with no headspace or introduced into an airtight chamber and mixed with water. An inert gas such as helium or nitrogen is bubbled through the water; this is known as purging or sparging.

The volatile compounds move into the headspace above the water and are drawn along a pressure gradient onto an adsorbent trap. Next, the trap is heated and the sample compounds are introduced to the GC column via a second heated transfer line, which is in line with the split inlet system on the GC or GC/MS. Purge and Trap in conjunction with a GC is well suited for volatile organic compounds (VOCs) and BTEX compounds (aromatic compounds associated with petroleum) in environmental samples and can also be used to sample volatile aromatic analytes in food and flavor samples.

The United States Environmental Protection Agency (USEPA) has promulgated a number of methods for the determination of VOCs. VOCs can be found in air, water and soil. The USEPA determinative methods include USEPA Methods 8260, 624, 8021 and 524 while the purge and trap preparative methods are USEPA Methods 5030 and 5035.

USEPA Method 5030 describes the purge and trap sampling of water and water miscible samples while Method 5035 describes the sampling of high concentration soil and waste sample extracts. Both of these sampling techniques can be done by the Evolution Purge and Trap concentrator and are outlined as proper sample preparation techniques for Method 8260D which involves employing a GC/MS for the VOC determinative technique. Other determinative methods that utilize the Evolution purge and trap are Method 8015 for the determination of gasoline compounds using GC/FID and Method 8021 which examines gasoline fractions by GC/PID. In order to determine VOCs in drinking water, the USEPA promulgated Method 524.